Sakichi Toyoda

Sakichi Toyoda

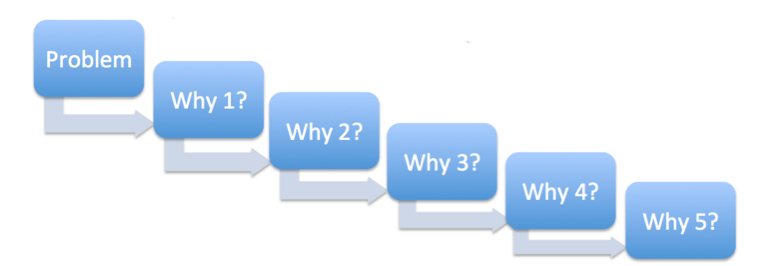

In the world of problem-solving and root cause analysis, the Five Whys technique stands out for its simplicity and effectiveness. Developed by Sakichi Toyoda at Toyota in the 1930s to augment Toyota’s lean manufacturing practices, it involves asking “Why?” five times (or as many times as needed) to uncover the root cause of a problem. In this blog post, we will explore how this technique works and how you can use it to address issues effectively.

What Is the Five Whys Analysis?

The Five Whys is a straightforward but powerful tool designed to get to the root cause of an issue. The idea is to ask “Why?” repeatedly until you identify the fundamental cause of the problem. It’s particularly useful in software development, manufacturing, quality control, and process improvement, but it can be applied in various fields. Here at ACV, we have been using the Five Whys Analysis to aid our Postmortem process after a Live Site Incident or LSI.

How It Works

-

Identify the Problem: Start by clearly defining the problem you’re facing. Be specific about what went wrong or what needs to be improved. In our case, this is typically the bug or problem that was on Production. For example, the problem might be that our users were not able to perform a critical business function on our website.

-

Ask the First Why: Question why the problem occurred. Focus on the immediate cause.

-

Ask the Second Why: Once you have an answer, ask why that specific cause happened. This helps to dig deeper.

-

Ask the Third Why: Continue questioning to uncover more underlying causes. Each answer should reveal a deeper level of the issue.

-

Ask the Fourth and Fifth Whys: Keep probing until you reach a root cause. Sometimes, it may take more than five questions, but five is a good starting point.

-

Address the Root Cause: Once you’ve identified the root cause, implement solutions to address it. Ensure these solutions are actionable and sustainable.

Example of the Five Whys Analysis

Let’s consider a simple example involving a user error seen on our website:

Problem: Users were not able to perform a critical business function on our website.

-

Why? The users were receiving an error when attempting to submit the form.

-

Why? The error was being generated because the connection request to the database was being refused.

-

Why? The database was refusing the connection because its memory was full.

-

Why? The database’s memory was full because there was a sudden increase in data being written to it.

-

Why? There was a sudden increase in writes because a new service started storing data into the database.

In this example, the root cause is that a new service started writing data to the database. The solution could be to increase the size of the database based on the estimated volume of data the new service will now be adding.

There may also be a solution around how changes like the new service being introduced are communicated to the organization to potentially prevent this problem in the future.

Benefits of the Five Whys

There are a lot of benefits of using the Five Whys Analysis.

-

Simplicity: The technique is easy to understand and apply.

-

Cost-Effective: It doesn’t require sophisticated tools or techniques.

-

Versatility: It can be used in various fields beyond software development including manufacturing, service industries, healthcare, and more.

-

Encourages Deep Thinking: By continually asking “Why?”, you’re encouraged to think critically and explore deeper causes.

Limitations of the Five Whys

It is important to note however, that the analysis technique isn’t perfect. Here are some common pitfalls to watch out for.

-

Superficial Analysis: Sometimes, the method may lead to a superficial understanding if not applied carefully.

-

Complex Problems: For complex issues with multiple causes, the Five Whys may oversimplify the problem.

-

Requires Expertise: Effective use of this technique often requires a good understanding of the process or system being analyzed.

Tips for Effective Use

To help overcome some of the short comings listed above, here are a few tips to leverage during your analysis.

-

Engage the Right People: Involve individuals who have a deep understanding of the process or issue.

-

Document the Process: Keep a record of each “Why?” and the answers to track the analysis. At ACV, we do this in our Postmortem document which is produced for every high urgency LSI we have.

-

Be Open-Minded: Sometimes the root cause may be different from what you initially expect. Be prepared to adjust your understanding. Take non-technical causes into account.

-

Follow Up: After identifying the root cause, ensure you implement and monitor the solutions to prevent recurrence.

Conclusion

The Five Whys is a valuable tool for problem-solving and root cause analysis. Its simplicity and effectiveness make it a go-to technique for many professionals. By systematically questioning and probing deeper, you can uncover the true causes of problems and implement solutions that address these fundamental issues. Remember, while it’s a powerful tool, it’s most effective when used thoughtfully and in conjunction with other problem-solving methods.